OMRON exhibits production inspection advances at SEMICON Taiwan 2025

OMRON works closely with global experts

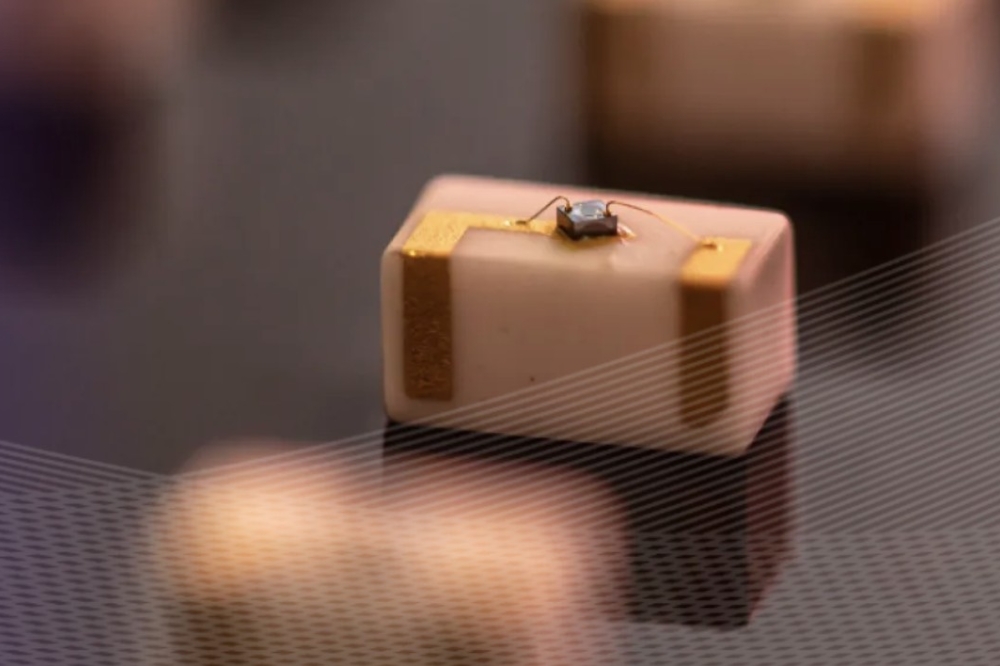

OMRON is pursuing research alongside current and future experts at the heart of Taiwan’s world-leading semiconductor industry. For example, the OMRON booth will highlight the company’s ongoing collaboration with the Mizuno Laboratory (School of Semiconductor Innovation and Sustainable Manufacturing) at National Cheng Kung University in Taiwan, led by Professor Jun Mizuno. Strengthening industry-academia cooperation, the partnership focuses on advanced packaging and heterogeneous integration technologies – exploring the potential for high-precision 3D X-ray inspection in semiconductor manufacturing and driving a revolution of quality for next-generation processes.

Professor Mizuno has dedicated many years to the research and applications of next-generation electronic and semiconductor materials, and packaging technologies. He is associated with the Japan Institute of Electronics Packaging (JIEP). Professor Mizuno quickly understood the great potential for non-destructive inspection offered by OMRON’s 3D X-ray technology, thus leading to this fruitful cooperation.

Also, in 2025, OMRON officially established the “Semiconductor & Incubation Center,” a dedicated unit focused on advancing technologies and market expansion in the semiconductor field.

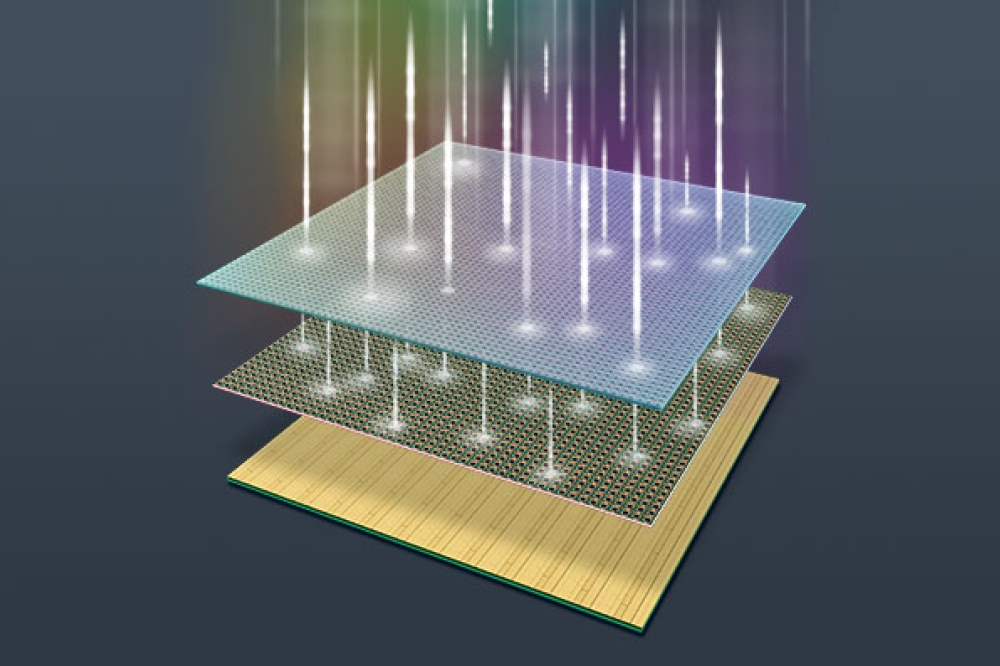

Digital Twin visualization technology

The integration of NVIDIA Omniverse with OMRON’s proprietary development platform, Sysmac Studio, enables a hyper-realistic digital twin that accurately replicates the operation status and inspection results of the X-ray systems. By leveraging the VT-X series, NVIDIA Omniverse, and advanced sensor control, OMRON enhances process visualization for engineers and enables smarter, more efficient quality management.

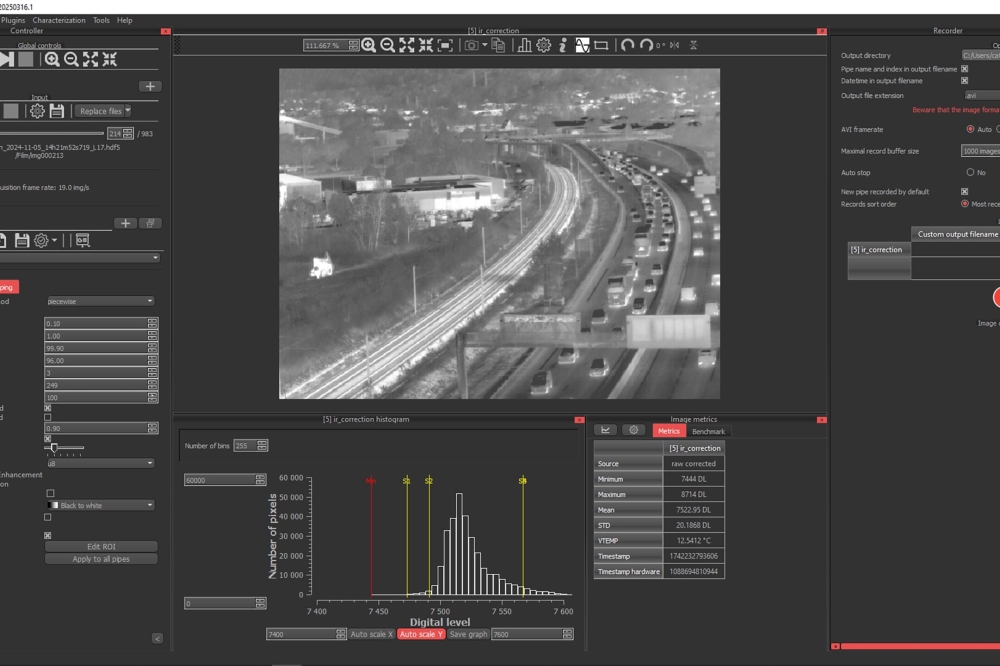

Real-time monitoring for competitive advantage

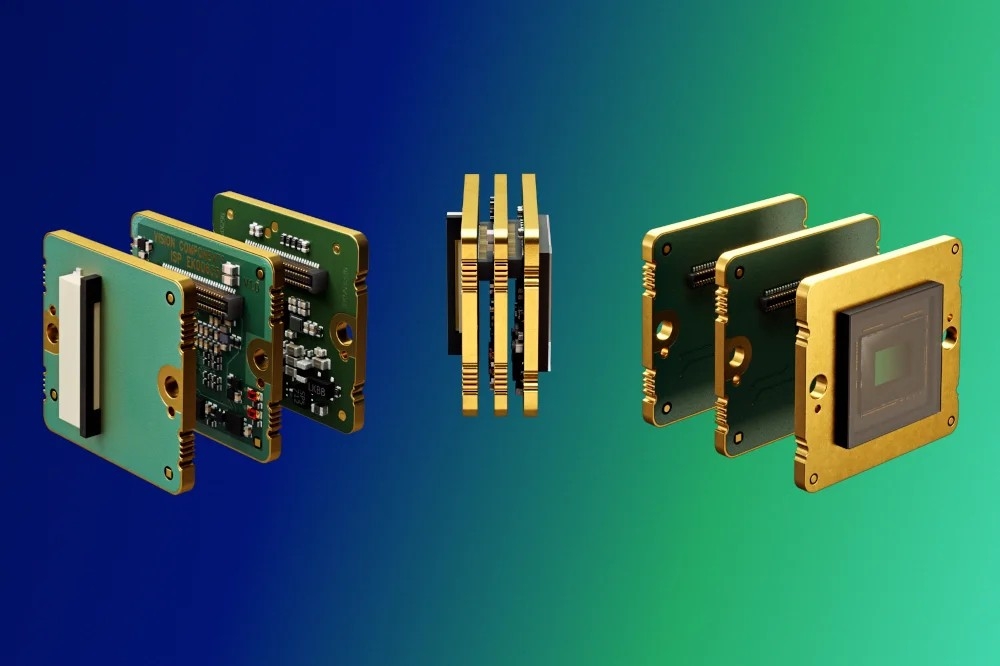

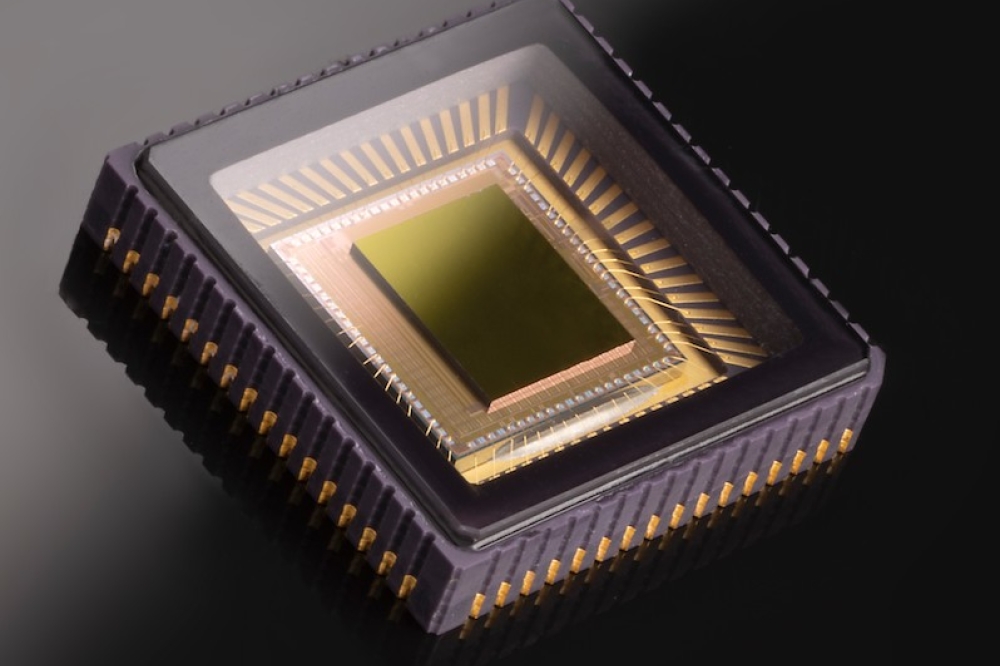

OMRON’s 3D-CT X-ray inspection equipment allows semiconductor manufacturers and packagers to monitor solder joint quality in real-time, starting from early R&D and then throughout the mass production process. Issues and errors deep within components and advanced packaging can be detected as soon as they appear, allowing immediate corrective action to save time and money. OMRON enhances the effect of all these technologies through sensor integration.

In the era of generative AI and ultra-fast data communications, semiconductor quality is critical. OMRON’s 3D-CT X-ray inspection line delivers real-time visualization, quantitative automatic inspection, and closed-loop feedback, supporting continuous production of high-quality devices. OMRON’s VT-X series of X-ray automatic inspection equipment is at the forefront, supporting the leaders in the race, who demand short lead times and rapid iterative development.

At SEMICON Taiwan 2025, OMRON’s lead and core development team will share behind-the-scenes insights into the development of the 3D CT X-ray inspection system, unveiling key challenges and technical breakthroughs from R&D through to mass production.

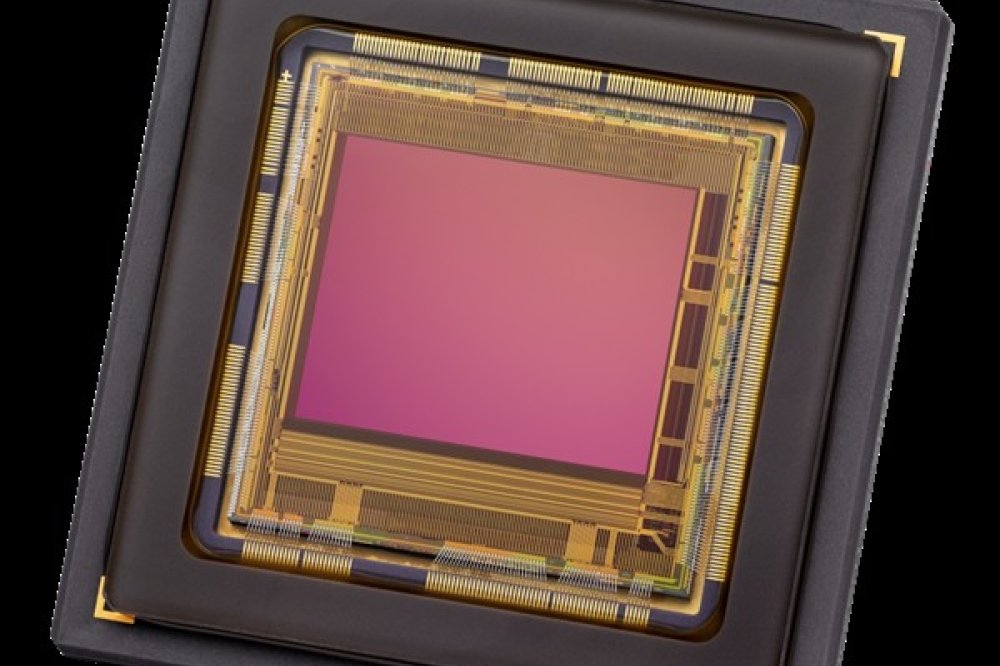

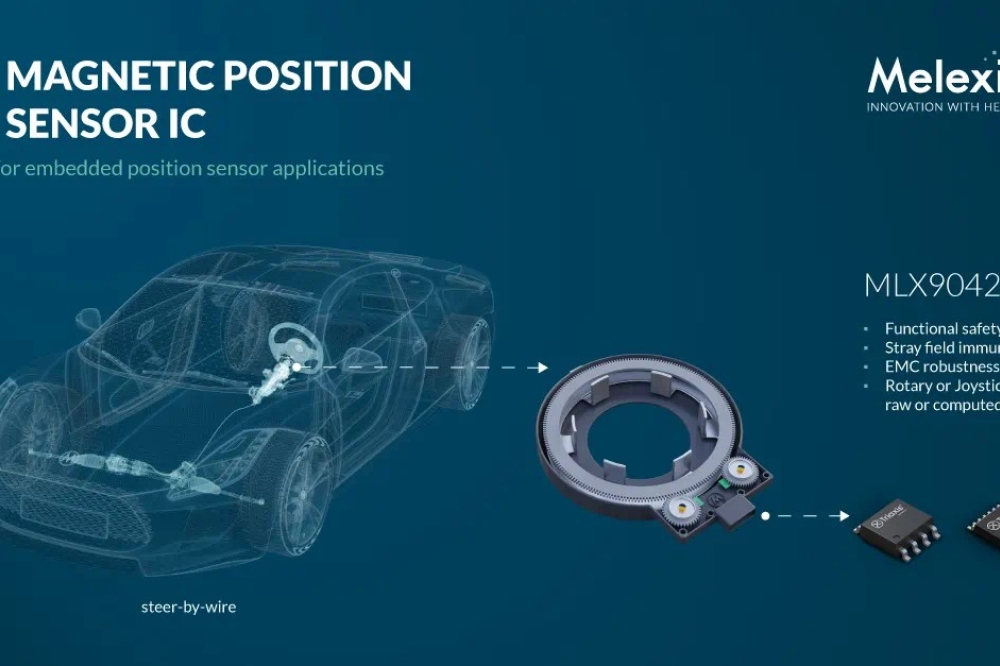

New ideas for hybrid bonding and glass panel inspection

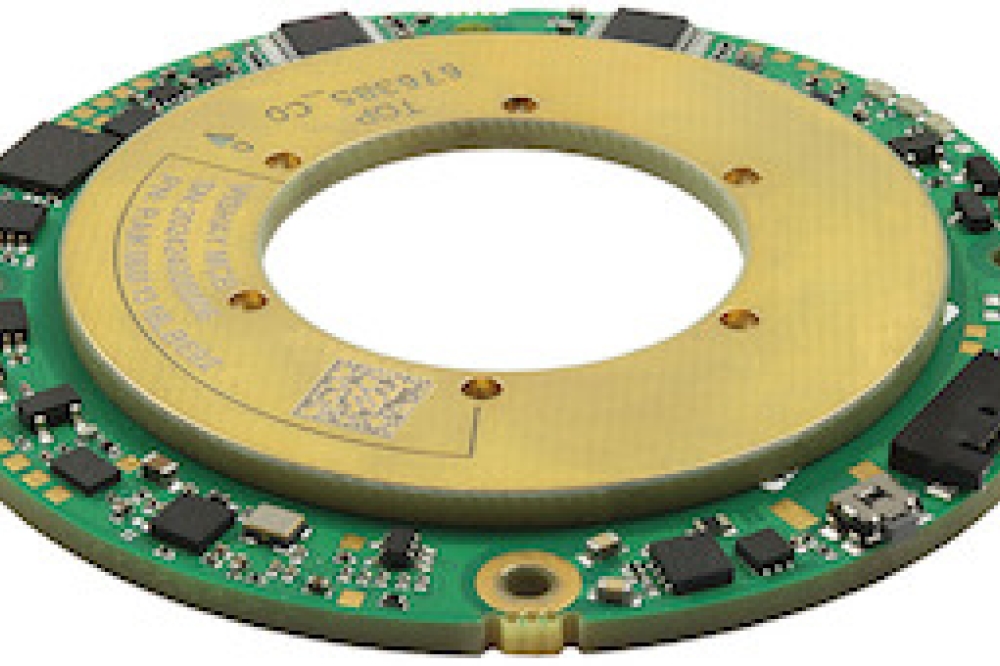

OMRON will showcase advanced reference solutions for the semiconductor industry, drawing on its extensive expertise in factory automation. These include high-precision position and force control technologies essential for W2W and D2W hybrid bonding (reference exhibit), real-time particle monitoring systems for equipment environments, and AI-powered defect inspection solutions capable of detecting chips and cracks in glass panels.